Artificial Rice Processing Line is productive, flexible and scalable line leverage Qunlong’s unique twin-screw extrusion technology and experience in product development.

Food Extruder Machines

From cereal and candy to pet food and treats, you’ve probably purchased a product made by a Qunlong Machinery Food Extruder Machine. We offer a full line of cold forming and cooking food extruders for a wide variety of food applications. Simplicity of design, flexibility in application, and ease of operation are the outstanding features of all Qunlong extruders. Our food extruder machines continuously maintain precise control of cooking temperatures, pressure, and time. Materials are extruded with consistent form, color, and properties.

FOOD EXTRUDER FOR PRODUCING EDIBLE MATERIALS

Each food extruder can be adapted and used for a wide variety of edible materials such as:

Snack Foods

Breakfast Cereals

Infant Foods

Pet Foods

Meat-like Products

Textured Vegetable Proteins

Gelatinized Starches

Corn Meal

Flour for Binders and Filler

FOOD COOKING EXTRUDER

Qunlong Cooking Extruders are highly adaptable to any operation. They are custom-made food extruder machines to suit your product-you don’t have to change your product to match your machines. Use as a stand-alone or in combination with a Qunlong Cooling Extruder for a unitized cooking, cooling, and extruding operation. Available in a full range of customized sizes, from 2” screw diameter, laboratory model, up through 10” diameter. The laboratory model can handle as small as 5 lb. sample batches and 40 to 250 lbs. per hour. The larger production line models have 4,000 lbs. to 5,000 lbs. per hour capacities.capacities.

FOOD COOKING EXTRUDER FEATURES INCLUDE:

Continuously cooks pre-mixed, dry, semi-moist, and moist foods. Eliminates “batch” cooking.

Maintains precise control of cooking temperatures, pressure, and time.

Hardened stainless steel liners for longer wear and easier cleaning to meet the highest sanitary requirements.

Can be fitted with rapidly interchangeable die plates for extrusion of an almost unlimited variety of shapes and sizes.

Robust designs for peak loads and sustained operations. Design simplicity and heavy-duty components mean fewer parts to wear out, less downtime, and significantly lower maintenance costs.

Modular design for adjusting temperature in each zone.

Different screw designs for differing products.

Variable-speed drive on screw to adjust retention time, pressure, and production rate

FOOD FORMING EXTRUDER

Qunlong is the leading supplier of extrusion equipment to the cereal, snack, and pet food industries. All extruders are engineered to meet and exceed peak load and sustained operation requirements. Simplicity of design and heavy-duty components mean fewer parts to wear out, less downtime, and significantly reduced maintenance costs. Our food extruder machines are available in a full range of customized sizes, from 2”, laboratory model, up through 17” diameter. The laboratory model can handle a minimum 2 lb. sample batches and trial runs of 40 lbs. to 250 lbs. per hour. The larger production line models have 8,000 lbs. to 15,000 lbs. per hour capacities.

FOOD FORMING EXTRUDER FEATURES INCLUDE:

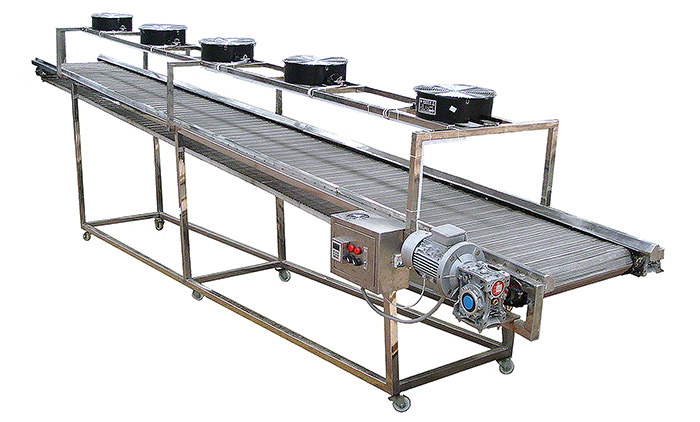

Uniform, controlled pressure, and temperature assured through use of liquid-cooled jacketed barrels and hollow screw.

Can be used as a stand-alone or in combination with Bonnot Cooking Extruder for unitized cooking, cooling, and extruding operation.

Stainless steel liners and hardened screw for longer wear and easier cleaning to meet the highest sanitary requirements.

Can be fitted with rapidly interchangeable die plates for extrusion of an almost unlimited variety of shapes and sizes.

Material is extruded gently through the die, eliminating high shearing stresses that affect product quality.

A wide choice of interchangeable screw and barrel configurations are available for processing various materials on the same basic equipment.

With QunlongMachinery you have the companion at your side that can food extrusion machinery supply you with a superlative remedy for your entire food processing tasks and also ventures. This process normally starts off with special type of applications and tools on a research laboratory range and also stretches right through to the commercial manufacturing plants. Over the course of time, we have registered ourselves as the world's leading food extrusion devices maker and also supply our food extrusion makers to a large series of sectors with our customers belonging from various parts of the world.

When your food extruder machines manufacturing processes require a specific type of food extrusion machines mixers or food extruder equipments, stoves, and various other efficient, economical solutions, QunlongMachinery usually fulfills the needs and demands of the makers all over the globe to make their procedure of production more secure, adaptable and a lot more organized than ever before.

As a constant innovator and manufacturer of the food extrusion equipments, we have a significant amount of riches as well as experience in this particular field. Setting up continuous new requirements in the food extrusion equipment, as well as its growth to bring something special onto the table for our customers all over the globe, we have actually gained substantial quantity respect and also affection for the food extruder devices we have been making. This shows our dedication in the direction of our reliable system and also capability towards innovating new items into the marketplace.

QunlongMachinery twin screw food extrusion machines supplies best conditions for the extrusion of various sorts of pet dog food and foodstuff. The processing area of our maker consists of different type of diverse barrels in which the food processing occurs.

The tightly-gapped screws around the food extrusion ans pasta extrusion machine operate completely offering the food an appropriate quantity of surface area, with their flawlessly secured self-wiping profile gets rid of the stagnant areas over the whole length of the process area. The outcome of this is regular high-conveying efficiency and transparency for cleaning up the equipment successfully. The style of our food extrusion equipment and also its irregular organization of the cost-free screw based quantity; its speed as well as torque make it possible for the food extruder machines to be totally set up for every and every application. The whole portfolio of the machine includes a huge range of sizes, aiding the customers to exercise the required throughput range from the production range to the lab. If you are willing to acquire an equipment from us or wish to purchase one in the future, feel free to contact us anytime.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語