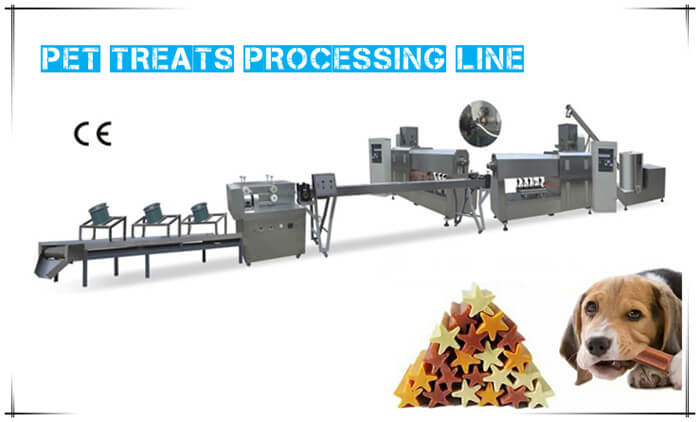

Dragons Machine provides a wide range of twin-screw extrusion Pet Food Processing Line.

Pet dog food is a food that is especially attended to pet dogs like pet dogs or cats as well as little pets. It's a top-quality animal food between human food as well as standard feed. Its major role is to give all sort of animals with nutrients of the most fundamental life guarantee, development as well as health needs. It has the advantages of thorough nourishment, high digestion and absorption price, clinical formula, high-quality criterion, practical feeding as well as usage, as well as can protect against particular diseases. Stable protein bar production devices are our recently made straight kind solitary row extrusion machine according to consumers' demand of smaller size and also reduced budget. the healthy protein bar machine can make protein bars, day bar, fruit bar, energy bar, nourishment bar, power bar and more.

Although pet food is animal feed, it is different from hen, duck, fish and cattle feed. For instance, the actual consumer of chicken feed is chicken, yet it is actually purchased by farmers. Farmers are looking for earnings, so they are not high-end consumers, they pay even more attention to quality as well as price. Pet dog is various, it resides in the city family; the real consumer of feline food or dog food is a pet cat or pet dog. However, the money to buy animal food is invested by family pet proprietor, and pet dog owners do not seek revenue, they pay even more interest to animal food high quality and brand rather than price, so they are high-end consumers.

1. Resources function as well as cleaning

Prepare all raw materials for making pet food as well as clean them.

2. Squashing

It guarantees all products are squashed right into called for dimension or powder.

3. Blending

The mixing process is a crucial procedure in animal food production. The standard process is to evaluate the raw products in different weight according to formula, after that pour them in the crusher to reduce size, and later on all materials are briefly saved in the storage space silo. Then all materials are ready, feed them in the mixer for blending.

4. Pet dog food extruding

Squeezing out is a heat therapy process with high temperature and also in short time. It can not just minimize the deterioration of food nutrients, enhance the digestibility of protein starch, yet additionally damage the anti-nutrient parts and microbe. All shapes of pet completely dry food such as round, triangular, blossom shape as well as bone shape can be produced via different mold and mildews (design templates) of the feed extruder maker. In family pet food production, fat is normally included in improving pet food palatability, as well as this is performed in the conditioning process. Besides, to give different shades to pet food tablet computers, producers usually include pigmented water in squeezing out chamber.

We provide both one-shot fill system with blended gravy as well as portions as well as a 2 shot fill system with different dosing of the chunks by multihead weigher and also sauce with volumetric dosing. With our recognize how and experience we support our clients not just with technological solutions but additionally with modern technology regarding dish growth and process improvements.

5. Drying out

The drying section is primarily used for eliminating water in the extruded pet food. After extrusion, the appearance of the material is fairly soft and also water content reaches 20 ~ 30%. After the drying procedure, the ended up item dampness is managed at 8% ~ 10%, which can ensure that the product is stored in a particular amount of time.

6. Oil as well as fat spraying

Oil and fat are the very best resource of energy, so 2% ~ 40% of oil as well as fat can be contributed to formula according to pet growth needs. We recommend that the content of the fat in the formula, that is the material of the overall oil in the extruder be kept within 12%. If the material of the oil is called for over 12% as well as the firmness of the granular material will certainly be considerably decreased. If the extruded material requires more than 12% oil content, the additional oil is suggested to be added in the means of external spray after drying. It can be utilized at regular pressure or vacuum spray depending on just how much oil is added. The outside splashing will make the pet food tablets appearance more tempting. In addition to oil, some powdered attractant is also sprayed to boost pet feed palatability.

Boost your procedure with our services! Please contact us, as well as we enjoy to give a demonstration.

Solutions.

Prior to sale solutions for pet food extruder

1. Supply the free appointment of the devices.

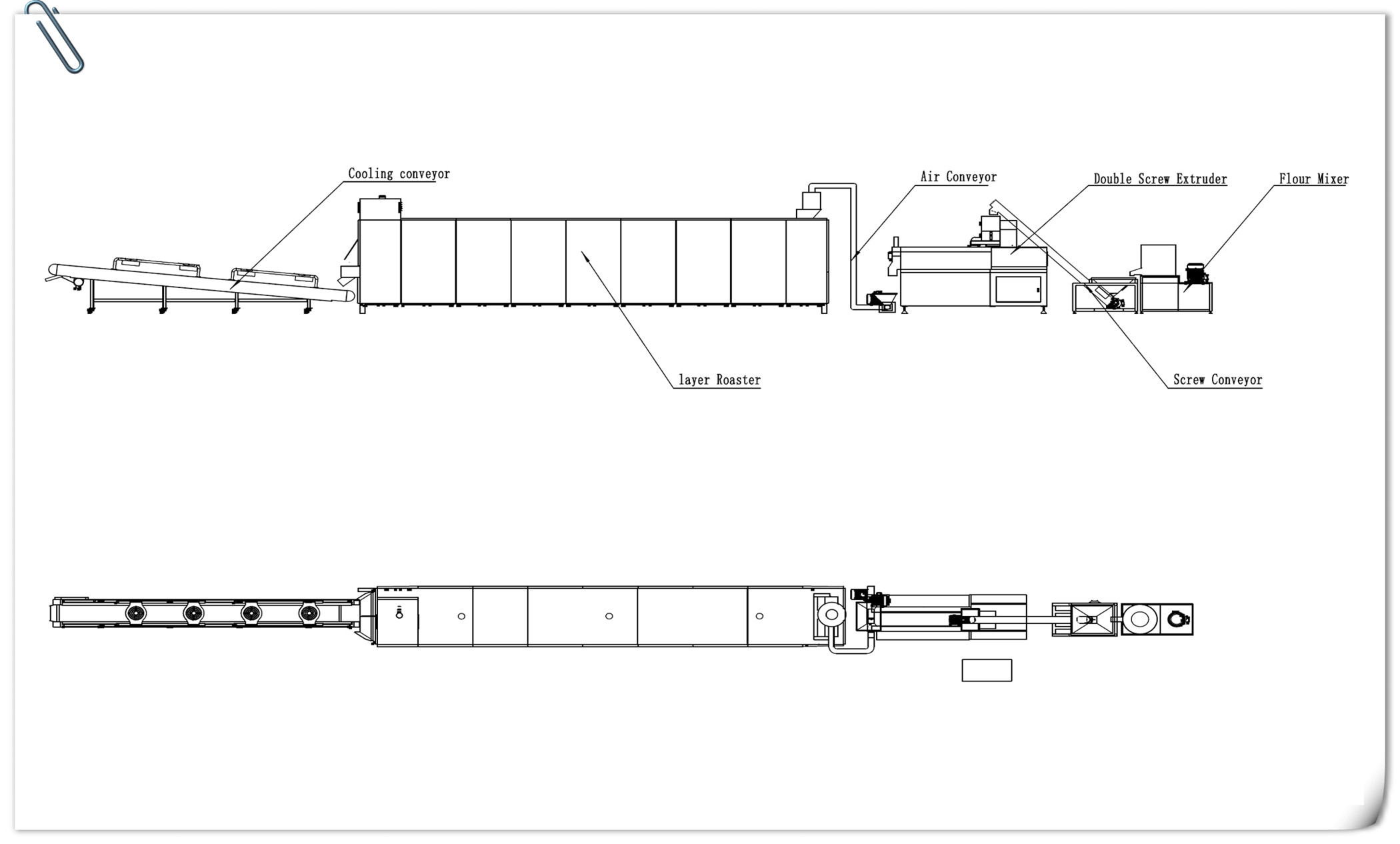

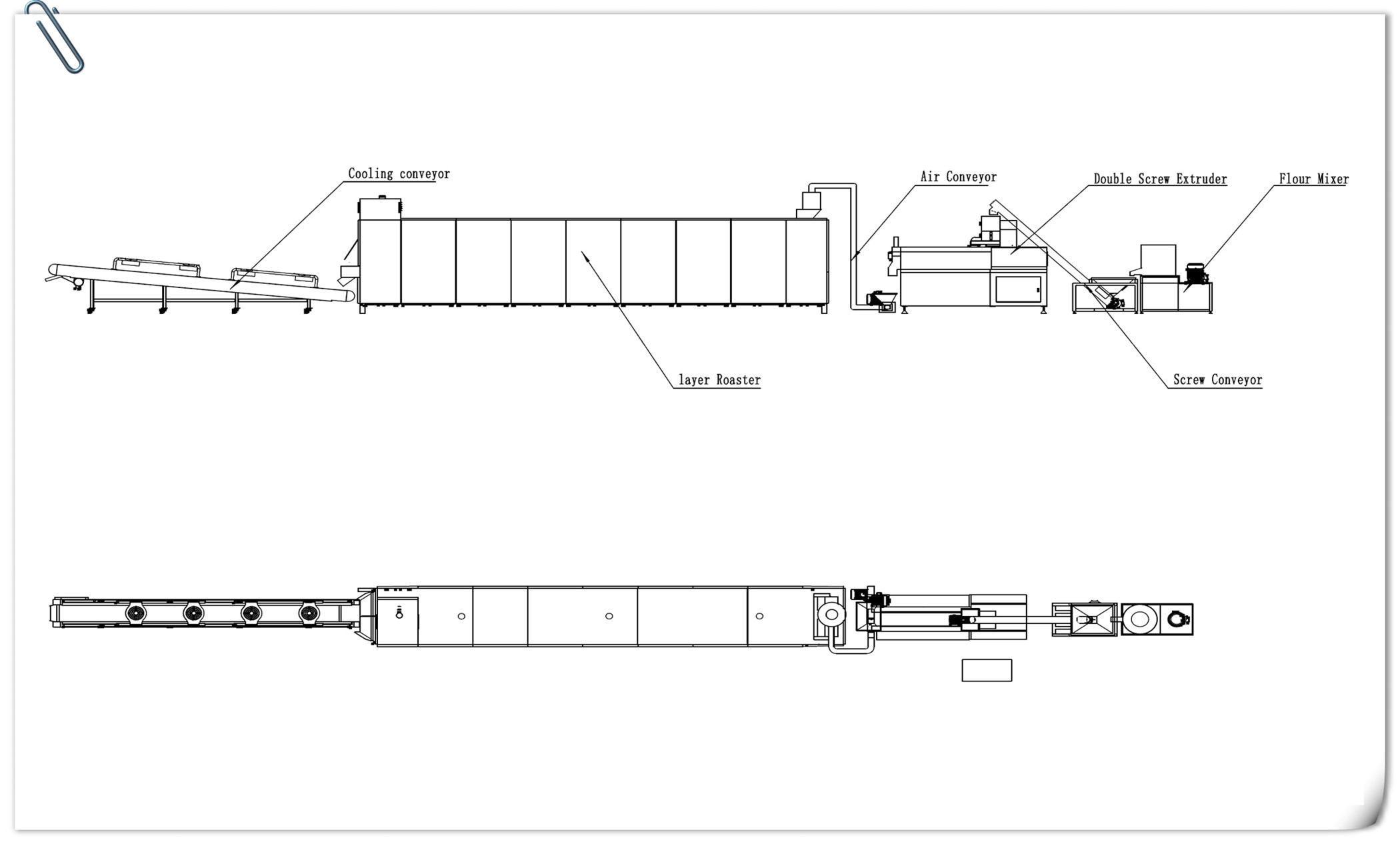

2. Supply the basic gadget as well as the flow sheet.

3. According to the customers' unique need, using the affordable strategy and also totally free design assisting to select the equipment.

Solutions throughout the sales for pet dog food extruder

1. Assist client layout the factory and offering expert suggestions, totally free design attracting for the manufacturing facility format.

2. Invite to visit our factory or the residential clients' factory.

3. Examine the device prior to leaving the manufacturing facility.

After sale services for pet dog food extruder

1. Oversea install as well as debug the devices.

2. Train the first-line driver.

3. Supply the basic formula

4. Procedure/ Service/ Upkeep Handbook: Given In English.

Advantages of Pet Food Extrusion Line:

1. Ingredient flexibility to process a large range of raw materials

2. Product integrity through very intensified mixing, resulting in homogenous melt, excellent starch gelatinization and protein matrix build up

3. Full control of process parameters and automation to ensure proper density levels and floating or sinking characteristics with high fat levels for salmonid fishes

4. Precise shaping and feed dimensions calibrated from 0.5 to 30.0 mm

5. Reduced maintenance, with standardized extrusion and drying spare parts, built-in easy access

6. Follow-up services, including training, process and technical support, design expertise, automation and technical upgrade.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語