Kurkure Making Machine

Kurkure Making Machine is used to produce kurkure snacks, cheeos, corn niknak. Kurkure / Cheetos / Niknak are special extruded snacks, very crunchy and delicious in taste.

Manufacturers that produce a variety of products, including the Kurkure processing plant, the Kurkure manufacturing machine, the Aluuga machine, the corn puff machine, the pulping machine and the macaroni manufacturing machine.

As a rich manufacturer and supplier of the qualitative series Kurkure processing plants for the food processing industry, our organization has been greatly appreciated. The processing plants we provide use the highest quality components and modern technology to manufacture, and comply with industry standards. We assure our customers that the processing plant has undergone quality tests on various parameters to maintain its flawlessness.

What is Kurkure Making Machine

The kurkure extruder machine is particularly developped to produce cheetos,kurkure, nik and so on. The kurkure ,cheetos, nik are usually baked or deep-fried to produce uneven crunchy foodstuff.

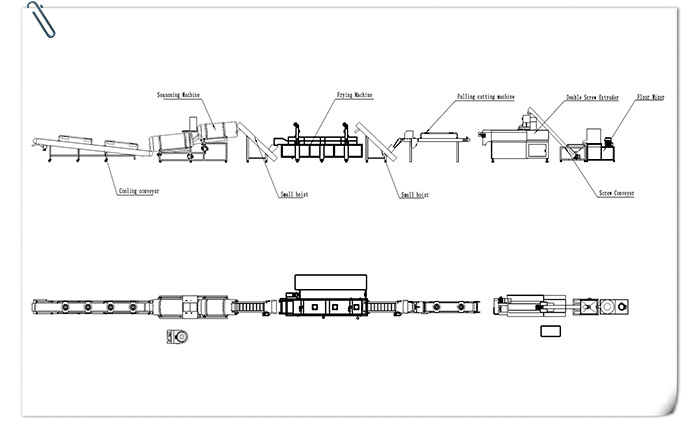

Working Principle of Kurkure Making Machine

Kurkure Making Machine uses corn grits as materials, which are moisturized in the flour mixer with water and fed to kurkure extrudsion machine.

In cheetos extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

At the exit of kurkure extruder, there has cutting knives can cut into required lengths.

Next Kurkure / Cheetos are fried in hot oil and then cooled before flavoring.

Finally, seasoning powder is sprayed, and coated on the surface to achieve different favorable tastes.

Kurkure Making System Advantage

Due to the delicious flavors and nutrition, Kurkure Making Machine is quite popular with consumers.

Kurkure Making System Application Scope :

| Model | Capacity | Power | Dimension |

| QL-100N | 100-150kg/hr | 96kw | 25 x 5 x 3m |

Manufacturing process description:

In the mixer, the raw materials are mixed and reach the required moisture content. The mixture is then transferred to the extruder hopper. The liquid level indicator can ensure that the extruder does not run dry. In the extruder, the high temperature generated by the high pressure accumulation of the screw and the shear force between the sleeve and the screw is used to press the raw material through the die. The pressure drop on the mold causes the snack to expand, and the noodle cutter sets the desired length and quality of the snack. After squeezing, deep-fried snacks to increase crispness and extend shelf life. Then coat them with oil and then with seasoning powder. The coating takes place in a rotating coating drum. Now the snacks can be packed. It's best to do it immediately. It is recommended to install a buffer silo between the packaging equipment and the production line, mainly to overcome the difference in operating speed. Kurkure or Niknaks extrusion is a process in which coarse grains (such as corn) are pressed through a mold into the final snack shape, and flavoring is added to make a delicious snack. Cereal puff snack food is a good snack food to enter the new market, because its raw material cost is low, and it can have many different appearances, which can easily inspire consumers. We manufacture and export Turnkey Kurkure manufacturing plant, snack manufacturing machine, snack extruder, barbecue seasoning machine, Turnkey complete snack manufacturing plant, kurkure manufacturing machine, Niknaks manufacturing machine, Kurkure extruder, Kurkure fryer, kurkure manufacturing machine, Corn puff manufacturing plant, turnkey factory for complete online manufacturing system, complete manufacturing plant,

In order to meet the diverse requirements of our prestigious customers, we are committed to providing Kurkure manufacturing machines with main bearing housings and bearings. These machines are manufactured using the highest quality components and advanced technology in accordance with industry specifications, so the quality is the best. In addition, customers can also obtain various designs and specifications of these machines from us at the listed price.

As an outstanding company, we are manufacturing and supplying efficient Qunlong machinery, which is widely demanded in different industries such as food and confectionery. The bhujia machines we provide are designed by skilled professionals, adopt advanced technology and the highest quality components, and keep pace with industry standards. The provided bhujia machines have been inspected by different quality measures to ensure their quality.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語