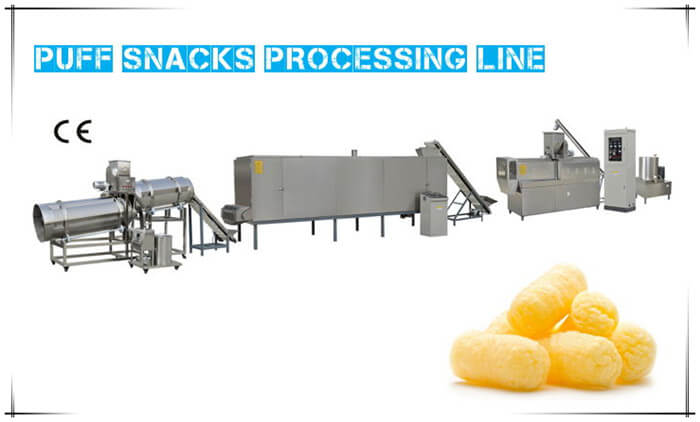

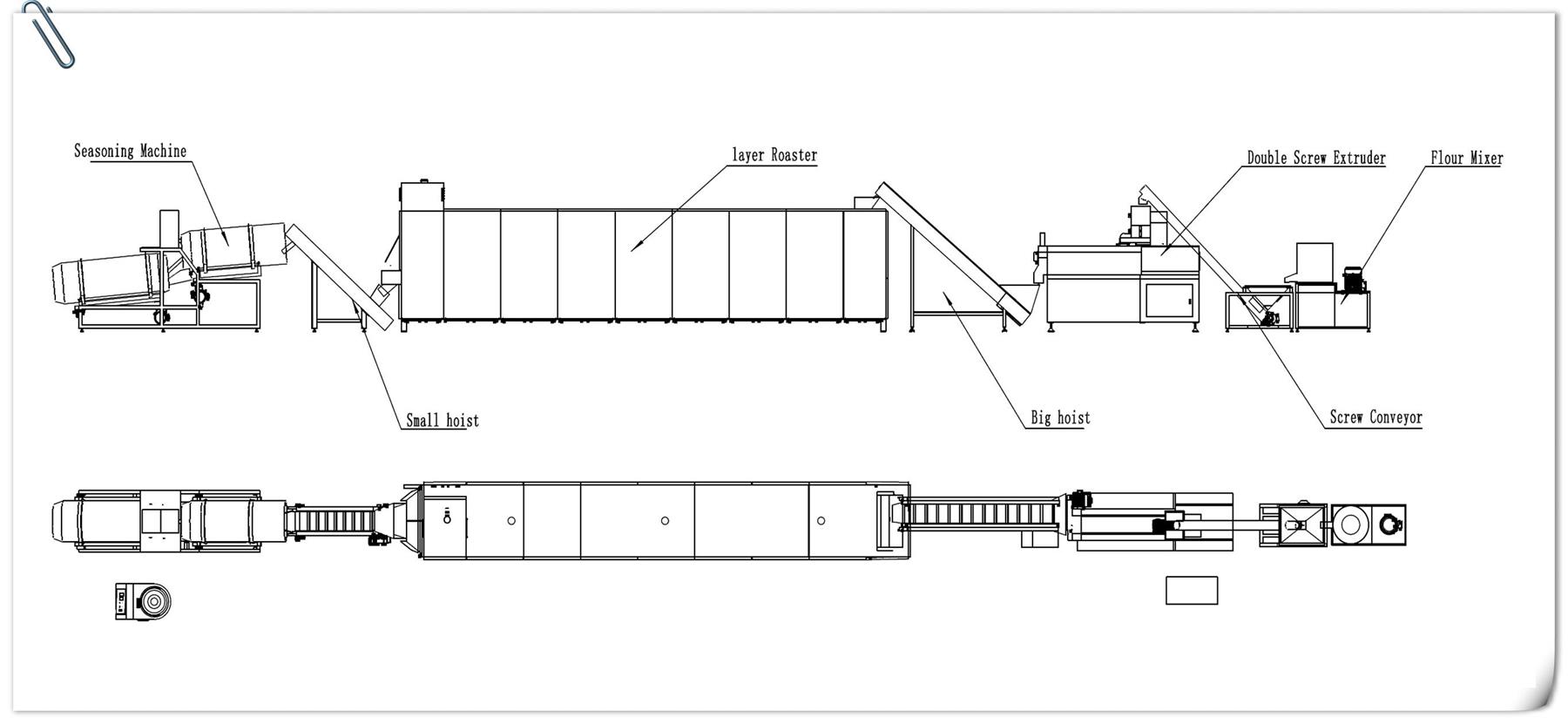

Food Extrusion Machine-Puff Snacks Processing Line

Puff Snacks Processing Line can process various direct cereal based snacks with a wide variety of recipes and shapes.

Puff Snacks Processing Line

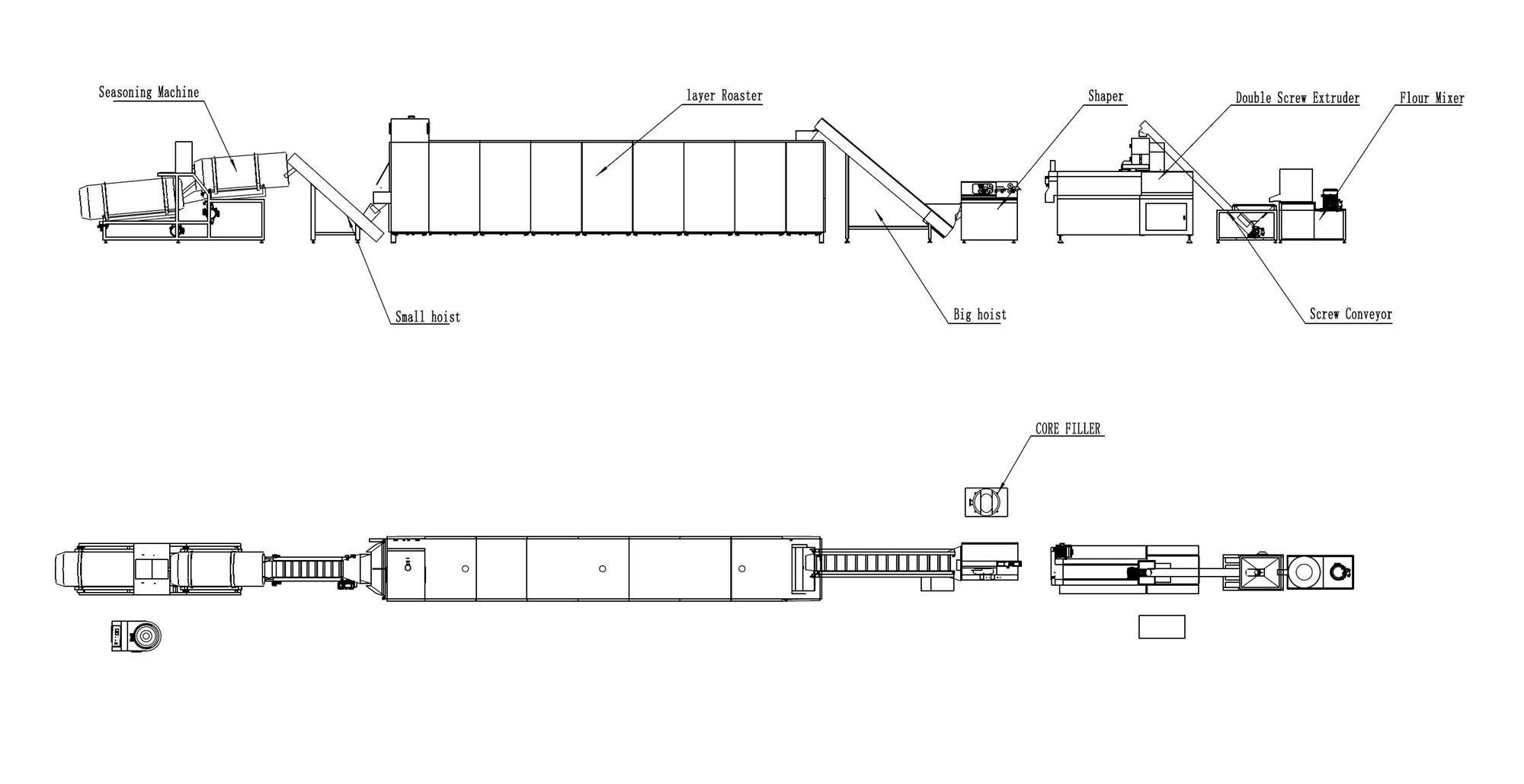

Food extrusion machine is a form of extrusion utilized in food processing. It is a process through which a collection of blended components are forced through an opening in a perforated plate or die with a style specific to the food, and are after that cut into a particular dimension by blades. The food extrusion equipment which requires the mix through the die is an extruder, and also the mix is called the extrudate. The extruder consists of a large, turning screw securely suitable within a stationary barrel, at the end of which is the die.

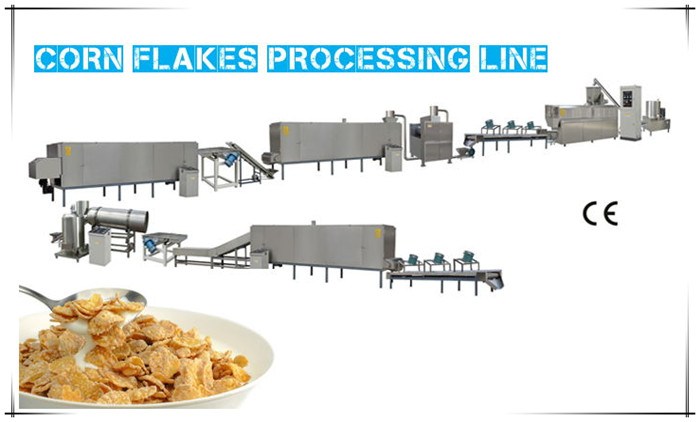

Food extrusion machine makes it possible for automation of food through a continuous, reliable system that ensures harmony of the end product. Food produced using food extrusion machine normally have a high starch content. These include some pasta, breads (croutons, bread sticks, and also flat breads), several morning meal cereals and also ready-to-eat treats, confectionery, pre-made cookie dough, some infant foods, full-fat soy, distinctive vegetable protein, some drinks, and completely dry and semi-moist animal foods.

What is an extruded snack made by food extrusion machine?

Blown and extruded treats consist of anything involving mixed components that are either pressed with a mold and mildew or accuracy cut. Examples include corn smokes, veggie straw snacks, pork rinds, cheese treats (puffs and also curls) and a lot more.

The advantages of the twin screw food extrusion machine

High productivity food extrusion machine: remarkable process-enhanced capability of twin screw food extrusion machine and also related process allows work advantage to be attained, for instance, continuous HTST processing, greater effectiveness because of decreasing cooling down time and also the account of component losses, power as well as water price lowered.

Incredibly versatile food extrusion machine: the identical twin screw food extrusion machine has the ability to process various sorts of ingredient to make a number of surface products;

Completely automated, with innovative operating protection; subsequently resulting in consistent producing the high quality extrusion food; while standard handling modern technology require duplicated adjusting of procedure variables.

Significantly suitable to new item growth, with the chance to focus on quickly the attributes of surface products that are flavor, savor, structure and nourishment;

History of food extrusion machine

The very first extruder was developed to produce sausages in the 1870s. Packaged dry pasta and also breakfast cereals have actually been generated through food extrusion machine given that the 1930s, as well as the technique was put on pet food manufacturing considering that the 1950s (initial extruded pet dog food in 1957 - Purina Dog Chow and first extruded cat food - Purina Friskies in 1962). It has likewise been incorporated into cooking area devices, such as meat mills, herb mills, coffee grinders, and some kinds of pasta makers. A similar functional procedure occurs when using bread bags.

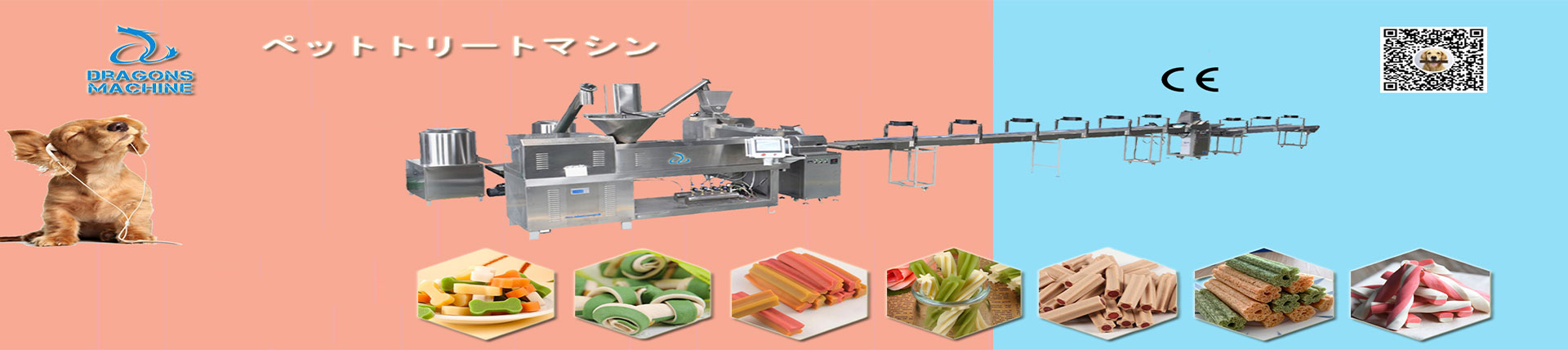

Jinan Qunlong Machinery Co., Ltd. (Hereafter called “Dragons Machine”) is an international high-tech enterprise, a council member of Chinese North China Pet Industry Association (CNCPIA), awarded by The National Quality Service Credit AAA Enterprise, which is majored in manufacturers of food extruder machine and pet food machine.

A pioneer in this industry, we provide twin-screw food extruder, pasta processing line, breakfast cereal processing machine, bread crumb processing machine, nutritious rice processing line and modified starch processing machine

By providing twin screw extruders, we have gained an extraordinary position in the industry. The starch extruder is used in various drilling fluid systems and is developed from quality-inspected components and conforms to established specifications. In addition, our customers can use various specifications of starch extruders according to customer requirements. The provided starch extruder is highly appreciated around the world due to its performance.

Starch extruder-pre-gelatinized starch pulping machine can produce modified starch. Pre-gelatinized starch is an effective and economical fluid loss reducer in water-based drilling fluids and is a derivative of starch.

At 120°C, it is not degraded by bacteria and is harmless and non-toxic to the environment. Modified starch can produce a thin, smooth, and tough filter cake, and increase the penetration rate by reducing friction. Can be used in various drilling fluid systems

By providing an excellent series of pasta processing lines, we have gained an extraordinary position in the industry. The processing line provided is developed using the best quality components and leading technology, while keeping in mind the established standards of the market. In addition, the processing line we provide has undergone various tests under the supervision of the supplier's quality control personnel to ensure that it is flawless. In addition,

the food extrusion machine production line can be provided according to customer requirements

Related News

Meeting With President Of TFPA Talked About Puff Snacks Extruder

Delivery Of Puff Snacks Extruder

Advantages of Puff Snacks Processing Line:

1. Productive and controlled manufacturing: continuous and automated high-capacity processing, fast automated changeovers, recording and management of settings and recipes, quick and easy die changes, easy cleaning and maintenance

2. Flexible, facilitating product innovation

3. A diversity of raw materials, using a wide range of ingredients (flour or meal using refined cereals, exotic raw materials such as classical cereals, etc.) and process flexibility to enable changes in product features (particle size, moisture or variable fat content)

4. A variety of operating conditions to produce specific textures and densities

5. A wide range of sizes, shapes and fillings (with optional co-extrusion kits)

6. Cost-effective: HTST (High Temperature Short Time) intensified transformation process generating savings in raw materials, water and energy; very hygienic processing and easy maintenance; compact design with reduced floor space requirements. Advanced automation designed by our experts ensures precise process control, resulting in consistent and repeatable quality.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語