Dragons Machine has updated Electrostatic Spray Workshop. This workshop is used to deal with the surface of the machine’s frame. Considering the factor of cost and the features of stainless steel (in high temperature, stainless steel will be out of shape), we normally use carbon steel to make the machine’s frame, so dealing with surface is necessary to provide rust protection.

For many suppliers, the frames are just painted with a spray gun, so the appearance is very bad, as the painting is not smooth and fixed. While heating the machine and the temperature is raised, the painting starts to peel off within a very short period. We can imagine, it is very dangerous if the painting chips falling down and mixing with the food materials!

So it is not small thing. We have specified Electrostatic Spray Workshop. Before entering the workshop, all the frames are polished by putty for 2-3 times to keep smooth surface. Then the frame enters the workshop and travels down a conveyor belt towards a paint booth, where it is sprayed with electrostatically charged paint particles. After the frame is coated, it continues on the conveyor belt to an oven, where the paint is cured. The benefits to the process of electrostatic coating is the ability to recover the little over-spray and having the process automated which will cut costs.

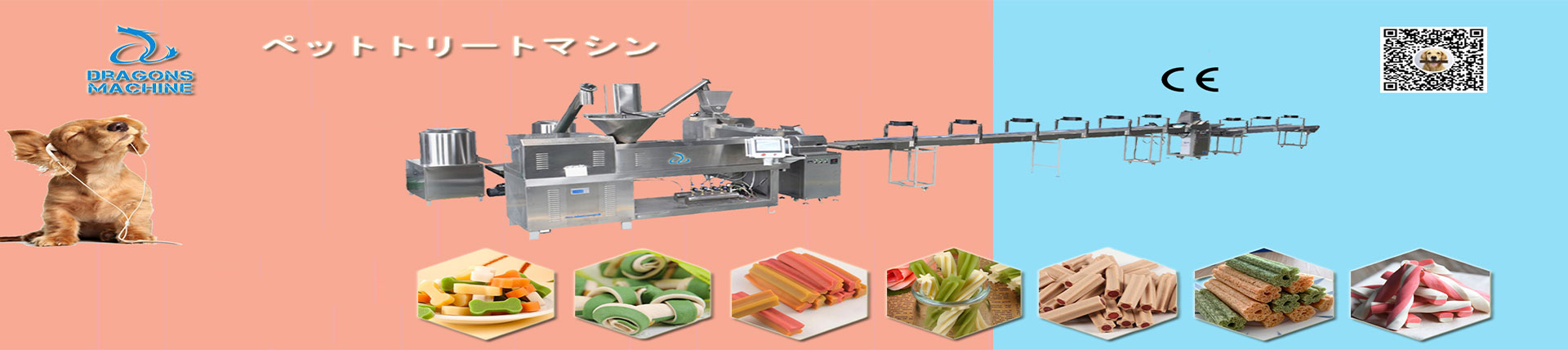

For all my machines, like Pet Food Machine, Pet Treats Machine, Corn Flakes Machine, Puff Snacks Machine, Cereal Bar Machine, Muesli Bar Machine, Granola Bar Machine, we all use this procedure.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語