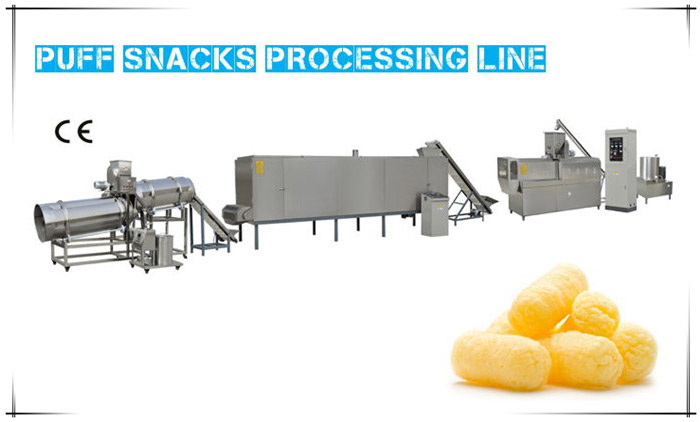

As a Food Extruder Machine Supplier, share some

information.

First, the cause of the damage of the Food Extruder

Machine and the barrel

Food Extruder Machine

1. The food extruder machine rotates in the barrel, and the friction between the material and the two causes the working surface of the extruder screw and the barrel to wear gradually: the diameter of the food extruder machine is gradually reduced, and the diameter of the inner hole of the barrel is gradually increased. In this way, the matching diameter gap between the food extruder machine and the barrel increases a little with the gradual wear of the two. However, since the resistance of the front head and the splitter plate of the barrel is not changed, this increases the leakage flow when the extruded material advances, that is, the amount of material flowing from the diameter gap

to the feed direction increases. As a result, the extruder production is reduced. This phenomenon causes the residence time of the material in the barrel to increase, causing the material to decompose. In the case of polyethylene, the hydrogen chloride gas produced by the decomposition enhances the corrosion of the food extruder machine and the barrel.

2. If there are fillers such as calcium carbonate and glass fiber in the material, it can accelerate the wear of the food extruder machine and the

barrel.

3. Since the material is not plasticized evenly, or metal foreign matter is

mixed into the material, the torque of the food extruder machine suddenly increases, which exceeds the strength limit of the food extruder machine,

causing the food extruder machine to be broken. This is unconventional accident damage.

Second, the repair of the Food extruder machine

1. The twisted food extruder machine should be considered according to the

actual inner diameter of the barrel, and the outer diameter deviation of the new food extruder machine is given according to the normal gap of the barrel.

2. Abrasion food extruder machine After the diameter of the threaded

surface is treated, the wear-resistant alloy is thermally sprayed and then ground to size. This method is generally processed and repaired by a

professional spray factory, and the cost is still relatively low.

3. Surfacing the wear-resistant alloy in the threaded portion of the worn food extruder machine. The weld was 2 mm thick according to the degree of wear of the food extruder machine, and then the size of the food extruder machine was ground. This wear-resistant alloy consists of materials such as C, Cr, Vi, Co, W, and B, which increases the anti-wear and corrosion resistance of the extruder screw. Professional surfacing plants have a high cost for this type of processing and are rarely used except for special requirements of extruder screws.

4. Repair food extruder machine can also use the surface hard chrome plating method, chromium is also wear-resistant and corrosion-resistant metal,

but the hard chrome layer is easier to fall off.

Our company also has a Cooking Mixer for sale. Welcome to

come and consult.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語