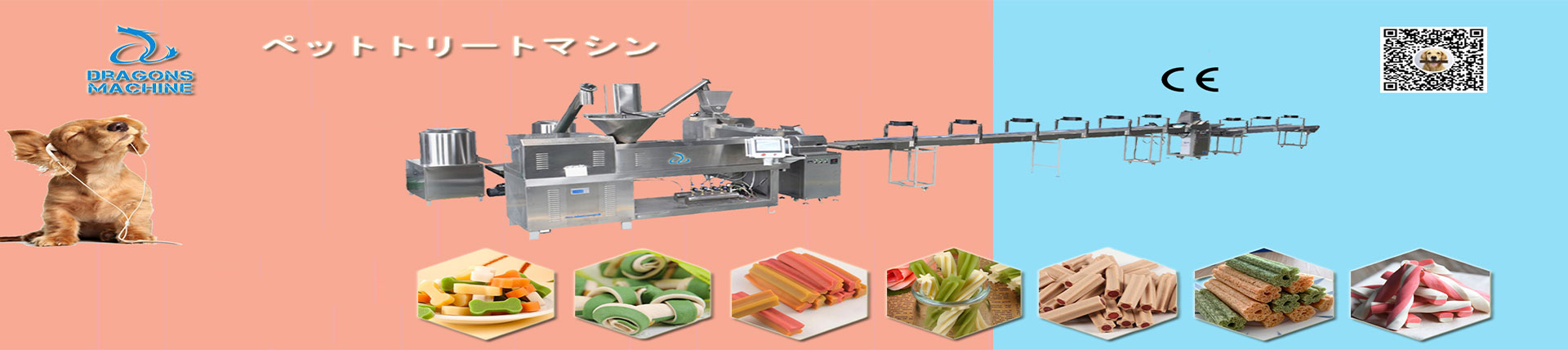

Dog Food Machine's puffing process: The puffing process is also a process of dog food raw material molding. During the molding process,

water is added in the form of steam to make the starch of the dog food

gelatinize, and the temperature rises to 100 degrees Celsius to 180 degrees

Celsius. Because the pressure before extrusion is very large, the pressure is

instantly released during extrusion, and the moisture is washed out of the particles. The dog food quickly expands and foams, and the water evaporates.

Therefore, the dog food that has undergone the puffing manufacturing process

generally has high nutritional value that is well absorbed. As a Pet

Food Processing Line Supplier, share with you.

Dog Snacks Moulding Machine

What's the effect of the puffing equipment?

First: Puffing equipment improves the palatability of dog food. The dry dog food becomes crispy after being puffed. The pet dog has a better taste during

the process of biting and swallowing, which is also conducive to cleaning the

teeth of the dog.

Second: Puffing can change and improve the nutritional value of dog food.

Many nutrients need to be matured and puffed before they can become nutritious.

Otherwise, it will not only bring effective nutrition to pet dogs but will also

cause diarrhea and vomiting.

Third: Puffing equipment can improve the digestibility and absorption rate of

dog food for pet dogs. For puffed dog food, pet dogs are more comprehensive and

perfect for absorption. At present, there is even a "double puffing" process,

the purpose is to allow pet dogs to more fully absorb the nutrients in dog

food;

Fourth: Through the process of puffing and making granules, the shape and

structure of dog food is changed, making it easier for pet dogs to eat dog food

and eat more;

Fifth: Puffing equipment can change the content of different nutrition

indicators of dog food. For example, reducing the moisture content can improve

the shelf life of dog food, making it easier for pet owners to store and feed at

any time, which is both safe and convenient;

Sixth: Change the density of dog food. Extrusion granulation and puffing can

also increase the bulk density of dog food, which is convenient for procurement

and transportation;

Seventh: The puffing process is also high temperature and high pressure

process, which can kill various harmful substances such as mold and improve the

safety and hygiene of dog food.

Dog food dryer: Dog food dryer is a belt continuous dryer, which is divided into two types according to the drying method. One is a general belt dryer,

which is divided into 5 meters and 3 layers of dryers and 5 meters and 5 layers.

Dryers, 8-meter 5-layer dryers and other models, most of the heating method is

electric heating or gas structure, the other for the new structure designed a

separate air circulation, mainly used for feed dehydration and drying treatment,

large capacity, Low energy consumption, mostly used in production lines with

large output. Our company also sells Dog Snacks Moulding

Machine, welcome to consult.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語